HSE Management System

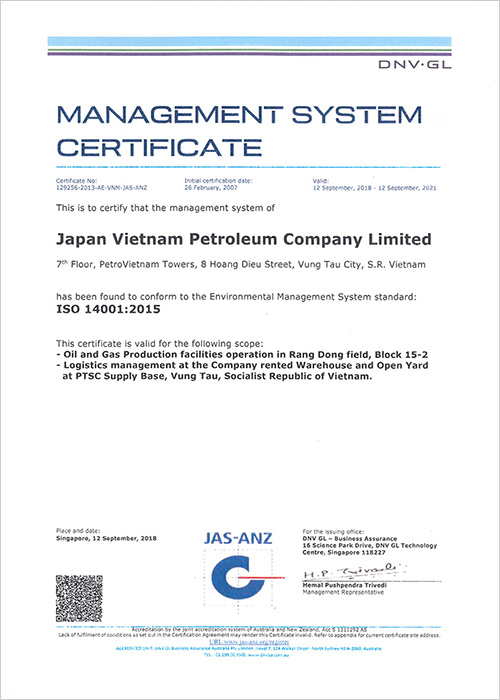

An HSE* Management System is a system pursuant to the HSE policy instituted by a company's top management. For us, it is a systematic platform to promote HSE activities in an effective and efficient manner by applying the PDCA cycle (plan, do, check and act) to organizations, roles and responsibilities, HSE plans, management procedures, and the like. Proper implementation of HSE Management System allows us to minimize and mitigate the risks leading to incidents and operational troubles.

- HSE is an acronym for "Health, Safety, and Environment."

The Operational Structure for Our HSE Management System

Risks of health impairment, operational incident, and impact on the global environment exist at each stage of the oil and natural gas development business: exploration, development, production, and abandonment. We position the management of such risks concerning occupational health, safety and the environment (HSE) as a matter of the highest priority in the execution of our business, and have built an occupational health, safety, and environmental management system (Management System) that is compliant with such international standards as ISO 14001*1 and ISO 45001*2. Pursuant to our HSE-MS, we have established an HSE Committee at our Tokyo Headquarters with our company president as the committee chairman and members of top management as committee members. We have also established an HSE Committee at each operations office, with each office chief serving as the committee chairman and division managers as committee members. We operate an HSE-MS that extends across the entire organization, and continuously carry out improvement activities aimed at preventing occupational accidents and minimizing environmental impacts. The Tokyo Headquarters' main functions under the HSE-MS are as follows.

- Setting annual HSE objectives that extend across the entire organization and managing progress toward them

- Jointly executing HSE emergency response exercises with both Tokyo Headquarters and NOEX branch offices, and performing consultations regarding the necessary points of improvement

- Sharing HSE statistical data and incident reports among all NOEX branch offices, and performing consultations regarding the necessary points of improvement with the incident analysis.

- Carrying out HSE audits for each NOEX branch office and performing consultations regarding the necessary points of improvement

- Holding HSE annual meetings together with NOEX branch offices, carried out by the HSE representatives and relevant staff of Tokyo Headquarters and each branch office, verifying performance toward HSE goals, and performing consultations regarding the necessary points of improvement.

- Providing HSE training for Tokyo Headquarters' personnel and fostering an HSE culture

- Recognizing branch offices that make outstanding achievements in HSE

- 1Environmental Management Systems--Specification with Guidance for Use

- 2Occupational Health and Safety Management System Specification

PDCA cycle of NOEX's HSE Management System

In order to promote HSE in an effective manner, we establish, implement, maintain and continually improve the HSE Management System, including the processes needed and their interactions, in accordance with the requirements of International Standards.

Application based on the PDCA cycle

Our HSE Management System is structured and operated in the form of the P (Plan) - D (Do = implementation and operation) - C (Check = checking and corrective action) - A (Act = management review) cycle.

We continually strive to improve our HSE performance by applying a cycle of "formulating HSE policy, objectives, and management processes," "implementing those processes," "reviewing and evaluating their compatibility with the policy/objectives and compliance obligations," and "continuous improvement."

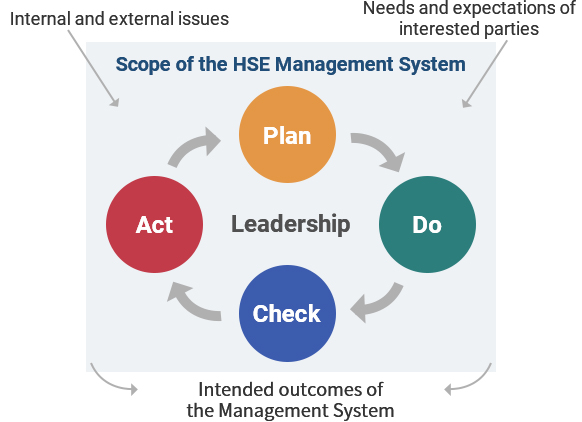

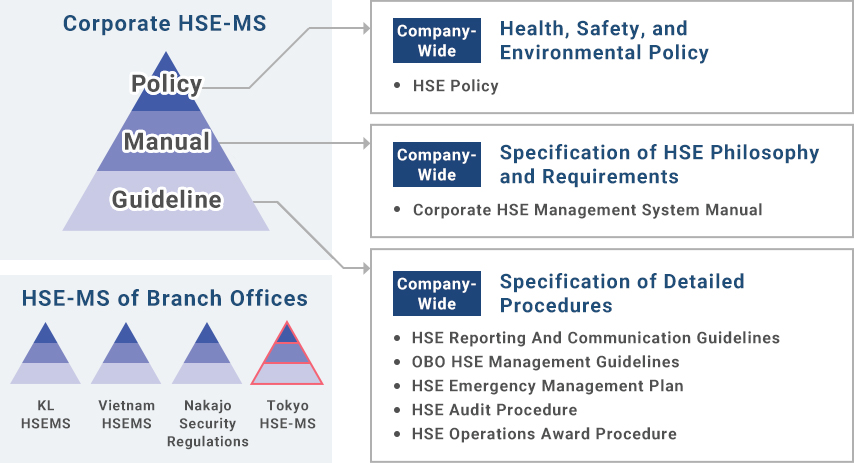

Organizational Structure of JX Nippon HSE Management System

We established the HSE Committee at Tokyo Headquarters to operate the JX Nippon HSE Management System effectively and efficiently. The committee is chaired by the president. The officer in charge serves as the management representative and general managers serve as members. The organizational structure is developed to define clear roles and responsibilities for the implementation of the JX Nippon HSE Management System.

HSE Documentation Hierarchy

Examples of Activities Based on Our HSE Management System

HSE Committee Meetings and Annual HSE Meetings with NOEX Branch Office Representatives

We formulate a medium-term environmental management plan (every three years) and HSE objectives and action plan (annually) to evaluate the effectiveness of our HSE Management System and improve HSE performance. The HSE Committee Secretariat monitors performance with respect to the HSE objectives and action plan and reports progress toward their achievement to the HSE Committee (twice yearly). Additionally, progress toward the achievement of HSE Committee-approved branch office HSE objectives is reported at HSE branch office meetings that are held once yearly and attended by the Head Office and branch offices. It is via this mechanism that we strive to continually improve our HSE activities through smooth in-house communication.

Emergency and Oil Spill Response

We prepare corporate Emergency Response Guidelines as part of our HSE Management System and develop systems that are based on site-specific emergency circumstances and oil spill response plans. With these plans, our response is organized in a tiered structure comprising the accident site, NOEX branch offices, and Tokyo Headquarters. Depending on the severity of the emergency, necessary resources and materials are mobilized to cater to each tier scale to minimize the impact on human life, the environment, and assets.

Tokyo Headquarters and NOEX branch offices regularly test the Emergency Response Guidelines through Emergency Response Exercises and make appropriate revisions based on the exercises' outcome.

To be able to promptly respond to a major oil spill, we utilize an industry mutual aid organization in Malaysia (PIMMAG), and engage industry-recognized oil spill response service providers in other countries. Further, taking lessons from the Macondo accident in the Gulf of Mexico, we have entered into agreements with well control response and subsea well capping services to deal with large-scale oil spills.

Regular Internal HSE Audits

We conduct an internal HSE audit of each branch office every one or two years. The purpose is to verify whether the branch office is implementing HSE activities based on its HSE Management Systems, and whether there might be obstacles or room for improvement in reaching HSE objectives by, for example, applying more energy to HSE activities, and then to provide advice and guidance if necessary. If negative findings are identified as a result of internal audit, the auditors and NOEX branch office will discuss and prepare an improvement plan and improve HSE performance accordingly.