Our involvement toward Safety

The risk of operational incidents exists at each stage of the oil and natural gas development business: exploration, development, production, and abandonment. We always endeavor to implement the most appropriate forms of risk management to ensure safer working environments and business operations.

Operations Safety

We conduct various HSE risk evaluations at the oil and natural gas exploration project planning stage and prepare measures to reduce identified risks. In addition, we make all staff who are engaged in operations aware of identified HSE risks and their countermeasures through HSE training, HSE meetings, and pre-work briefing sessions, thereby enhancing the countermeasures' effectiveness.

To further reduce operational risks, we promote such HSE system and operational procedure as STOP,*1 JSA,*2, and PTW.*3 At the same time, managers at NOEX branch offices evaluate their staff members' operational competency and provide training programs to ensure that operations properly fulfill HSE requirements.

- 1Safety Training Observation Program

- 2Job Safety Analysis

- 3Permit-to-Work

Safety Performance

No fatal incidents have occurred in recent years.

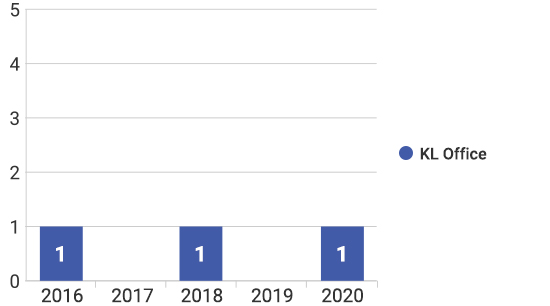

Number of Lost Workday Cases (Last 5 years)

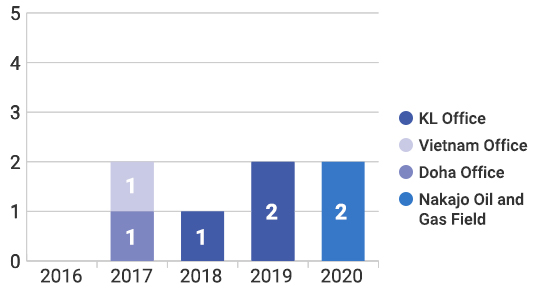

Number of Restricted Workday Cases (Last 5 years)

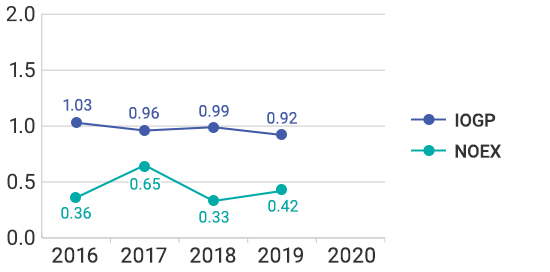

Frequency of Recordable Incidents

Total recordable incident cases (lost work day cases + restricted work day cases + medical treatment cases) per million man-hours is referred to as TRIR.*1 TRIR is used as an index to express the frequency of occupational incidents. Our TRIR consistently falls below the industry average published by the IOGP.*2

- 1TRIR: Total Recordable Injury Rate

- 2IOGP: International Association of Oil & Gas Producers

Building of HSE Culture

HSE seminars are organized in Tokyo HQ from time to time to enhance awareness of HSE and build an HSE culture by inviting lecturers for selected topics. In 2019, a "seminar on the evaluation and management of production facility integrity" was held and attended by many employees. Additionally, "Training to sensate danger and safety awareness" was provided at the Sensate Danger Training Center to raise employee awareness.

Our overseas offices have safety award programs that recognize NOEX employees as well as contractors' employees who actively participated in HSE. These programs serve to raise safety awareness and stimulate HSE activities.

Safety Operation Award

We have received many HSE awards over the years from local governments and regulatory authorities for our Zero LTI record and continuous HSE efforts.

Nakajo Field Office (Japan)

In 2016, the Nakajo Field Office was recognized for the first time with a safety award from the Safety Association of Hazardous Materials in Kanto and Koshin Divisions. The award was presented in recognition of the office's strict compliance with the Fire Service Act and 50 years of consistent hazardous materials safety management in outdoor storage tanks and other facilities. The office was selected as the only recipient among nearly 300 member plants and offices.

HSE Operation Awards

The "HSE Operation Awards" program was launched to encourage branch offices to promote HSE programs. In 2018, "HSE Operation Awards" were given to two offices that met prescribed safety and environmental criteria.

In 2019, a new scheme, called the "HSE Long-Term Operations Awards," was added to the HSE Operation Awards. It recognizes facilities that maintain an excellent HSE track record for more than five years.